23 June 2023. Authored by Henry Turner. Time to read: 9 minutes.

Understanding the Role of Computer-aided Design in Engineering

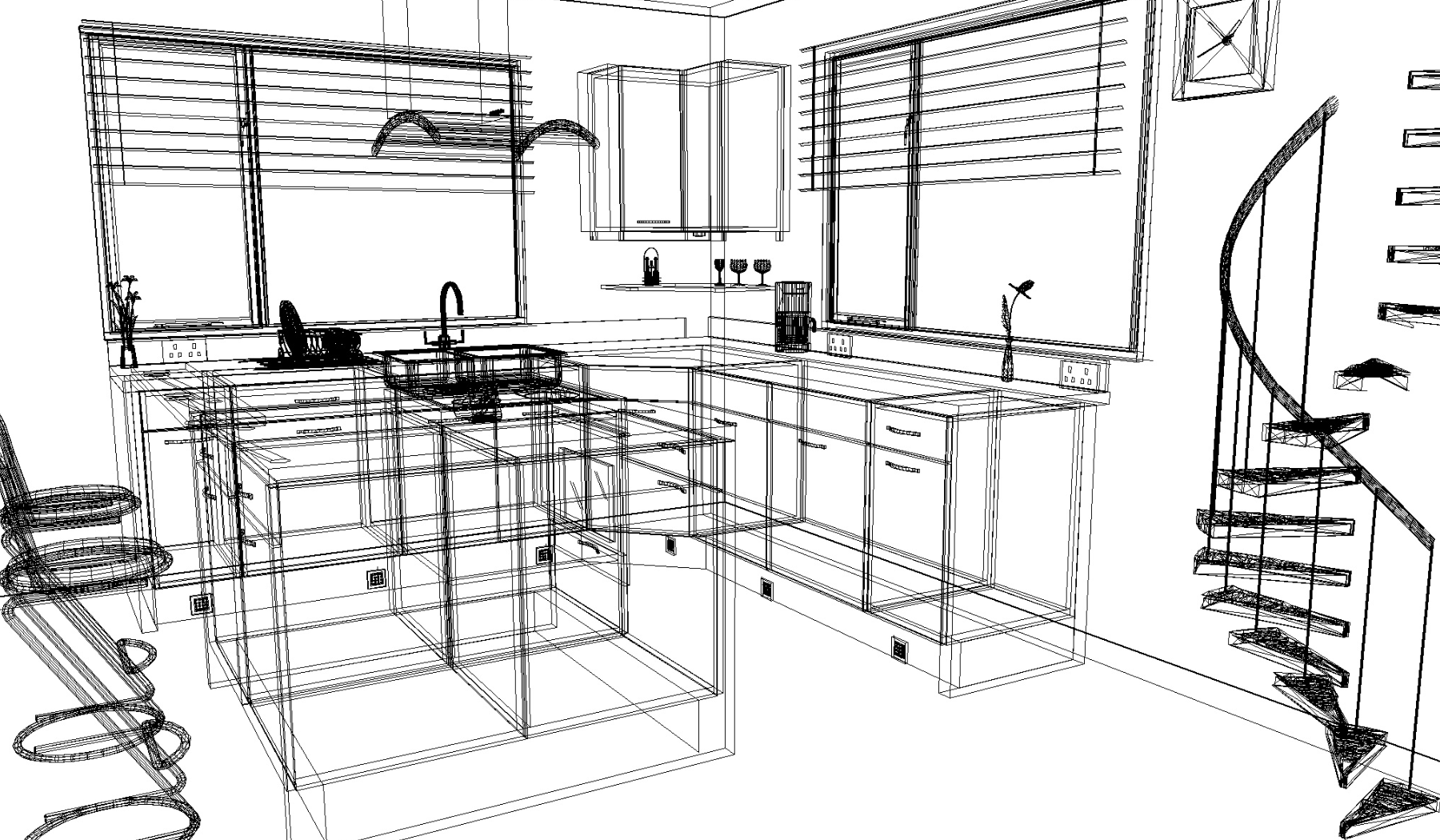

Computer-aided design, or CAD, is a vital tool in engineering that allows designers to create detailed, accurate, and efficient models of products and structures. With the help of CAD software, engineers can design products with precision and ease, while also making sure that the designs are compliant with relevant standards and regulations. By providing a 3D visual representation of the design, CAD enables engineers to identify flaws and make changes before the final product is made.

CAD software has revolutionized the way engineers work and has significantly reduced the time and cost involved in the design process. With CAD software, engineers can create, modify, and optimize designs in a virtual environment, allowing them to test different scenarios and make design changes in real-time. As a result, CAD has become an essential tool for engineers working in a variety of fields, from aerospace and automotive engineering to architectural design and product development.

For more information on the power and applications of computer-aided design, check out How Does Multicolor 3D Printing Work?

How CAD Enhances Accuracy in the Design Process

CAD software plays a key role in enhancing accuracy in the design process by allowing engineers to create highly detailed and realistic virtual models of their products. With 3D CAD, engineers can visualize every aspect of their design, from the structure and mechanical components to the electrical and electronic systems. This visualization allows for greater accuracy in designing and prototyping the product, as well as testing, simulating, and validating its performance.

Another way CAD enhances accuracy is by detecting any design flaws or errors early in the design process before the product is actually built. CAD software includes a range of features that allow designers to check for potential issues and errors, such as conflicts with other components, and make necessary changes. As a result, engineers can ensure that their designs are highly accurate and that the final product meets all specifications and requirements.

To learn more about how CAD software can enhance the design process and improve product accuracy and efficiency, visit How Does Multicolor 3D Printing Work?.

The Impact of CAD on Efficiency in Engineering

The integration of CAD in the engineering process has significantly impacted the efficiency of engineers by providing a virtual environment where design and modeling of products and structures can be done with speed and preciseness. Before CAD, designers would have to sketch out their ideas on paper or create a physical model of the product to communicate their design intent. With CAD, the design process is much faster, accurate and streamlined, allowing engineers to focus more on the creative aspect of the process rather than lengthy technicalities. Factors like cost, material choice, simulation, and feasibility can now be tested, edited and optimized with ease, thus reducing the time and cost involved in product development.

The effective use of CAD offers engineers a perfect opportunity to create and manage a database of designs specific to their needs. This provides an efficient method of reusing a specific design thereby reducing the possibility of redundancy and inconsistencies. The automated nature of computer-aided design also allows for quick modifications to be made to the design without much effort, leading to a more productive and flexible workplace. Overall, CAD has immensely impacted the engineering field, from increased productivity and accuracy to saving time and cost, all while ensuring that products meet required standards.

For more information on the importance of CAD in the engineering industry, visit How does OCR Work? A Short Explanation.

Case Study: Real-world Examples of CAD Implementation

The integration of CAD in engineering has led to reduced product development costs and increased efficiency, as can be seen from real-world examples. For instance, in the automotive industry, CAD tools are utilized to develop designs with enhanced aerodynamics resulting in better fuel economy, increased safety of the driver, and an overall better experience for the passengers. Engineers can now design engine components, automotive body parts, and car interiors with more precision, meaning no wasted materials and an effortless structure assembly. In aerospace, CAD is widely used to design highly complex parts that allow for a reduction in product development time and cost, leading to added fuel efficiency and safety of travelers.

In the construction industry, CAD has revolutionized the blueprint and design process by providing a more accurate representation of the building and all its intricacies. Gone are the days when buildings were constructed by mere human imagination. With CAD software, architects and designers can create complex designs that builders can replicate with exact precision, the result: buildings of greater durability, safety, and better functionality.

These case studies are just a glimpse of how CAD has revolutionized the engineering industry, proving to be a highly invaluable tool in product development, design, optimization, and performance testing.

The Future of CAD in Engineering

As technology continues to advance, the role of CAD in engineering is becoming even more crucial. One of the key developments is the integration of CAD software with other engineering tools such as simulation and analysis software. This integration allows engineers to design and test the product in a virtual environment, providing a more accurate and efficient way of designing and validating products. In addition, the use of artificial intelligence and machine learning in CAD software is helping to automate some of the design tasks and improve overall design efficiency.

Another key trend in the future of CAD is the use of cloud-based CAD software. With cloud-based CAD, engineers can easily access and collaborate on designs from anywhere in the world, which is especially useful for global engineering projects. Furthermore, newer CAD software is increasingly user-friendly, featuring intuitive interfaces that require minimal training, allowing more people to design and collaborate on projects using CAD. As the demand for flexible, cost-efficient, and collaborative engineering solutions grows, cloud-based CAD is becoming more and more popular.

Conclusion: Emphasizing the Importance of CAD in Modern Engineering Practices

In conclusion, CAD is rapidly becoming an indispensable tool in modern engineering practices. From architecture and product design to aerospace and automotive engineering, CAD software has revolutionized the way engineers design and test products, reduced the time and cost involved in the design process, and increased product accuracy and efficiency. As CAD software continues to evolve, incorporating new technologies such as cloud computing and artificial intelligence, it is likely that the role of CAD in engineering will only become more critical. If you’re looking to learn more about CAD software and its applications in architecture, check out How Industries Use CAD: Architecture.