24 June 2023. Written by Alexander Parker. Approximate time required: 4 minutes.

The Initial Cost of a CNC Machine Is Only the Beginning of Your Investment

Investing in a CNC machine can bring significant advantages to your business. You can make more accurate, complex, and high-quality parts faster and more efficiently than with traditional techniques. However, buying a CNC machine is not just a one-time investment. Although the initial cost may seem high, it’s only the beginning of your financial commitment.

You need to consider other expenses, such as tooling, software, operator training, and upgrades, to get the most out of your machine. For example, using a subpar or outdated software package can hinder your productivity, quality, and profitability. On the other hand, investing in a high-quality Computer-Aided Design (CAD) software can boost your precision, creativity, and collaboration.

Moreover, you need to allocate resources for maintenance and repair, which are essential to keep your CNC machine in good working order. Neglecting these aspects can lead to downtime, errors, and safety hazards, which can be costly in the long run. It’s better to have a preventive maintenance plan that includes periodic inspections, cleaning, lubrication, and replacement of worn or damaged parts.

Therefore, before selecting a CNC machine, you should assess not only its initial cost but also its overall value proposition. Consider the quality, features, versatility, and durability of the machine, as well as its compatibility with your existing equipment and processes. Also, evaluate its operating cost, energy efficiency, and environmental impact, as these factors can affect your bottom line and reputation.

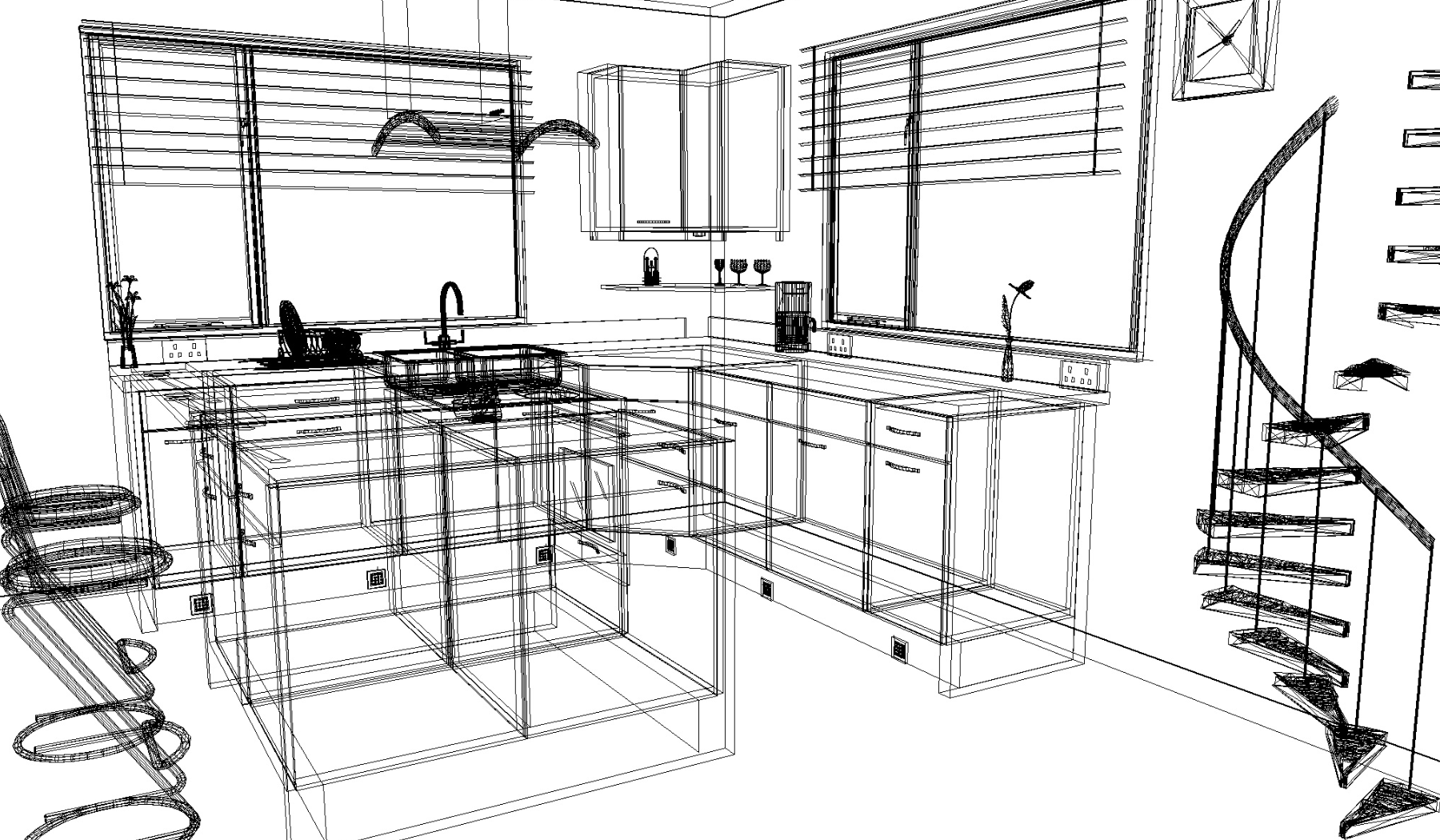

If you want to learn more about how industries use CAD, check out this article on How Industries Use CAD: Architecture.

Regular Maintenance and Repair Costs Should Be Factored into Your Budget

Like any machine, CNC machines require regular maintenance and repair to perform at their best. However, these costs can sometimes be overlooked or underestimated, leading to unexpected downtime, breakdowns, and expenses. Therefore, it’s crucial to factor in these costs when planning your budget and production schedule.

The frequency and scope of maintenance and repair depend on various factors, such as the type of machine, the usage, the environment, the quality of the materials and cutting tools, and the level of operator skill. However, some common practices can help you reduce the risks and costs of downtime and repairs.

Firstly, it’s essential to follow the manufacturer’s recommendations for maintenance and service. These can include daily, weekly, monthly, or yearly tasks, such as cleaning, lubrication, calibration, inspection, and replacement of consumables or parts. It’s also recommended to keep a record of these tasks, to monitor the machine’s performance and anticipate any wear and tear that could affect it.

Secondly, it’s important to train your operators on how to use and maintain the CNC machine properly. They should be familiar with the machine’s features, controls, and safety procedures, as well as the best practices for tool loading, unloading, and storage. They should also know how to identify and report any abnormalities or potential issues, before they escalate into more serious problems.

Thirdly, it can be beneficial to invest in a preventive maintenance agreement or contract with a reputable service provider. This can give you peace of mind that your machine is being inspected and serviced by professionals, who can detect and fix any issues quickly and efficiently. It can also help you budget your maintenance costs, as you can spread them over a certain period, and avoid any surprise expenses.

In conclusion, CNC machines can be a valuable asset for your business if you plan and budget for their costs and maintenance. By doing so, you can minimize the risks of downtime, quality issues, and safety hazards, and maximize your productivity, profitability, and customer satisfaction.

Consider the Cost of Training and Hiring Skilled Operators

When investing in CNC machines for your business, it’s not just about the cost of the machine itself. It’s important to consider the cost of training and hiring skilled operators who can operate and maintain the machine to maximize your investment. You may be able to save on costs by hiring inexperienced operators, but this could be risky as using CNC machines require specific skills and knowledge. An unskilled operator could cause a lot of damage to the machine, resulting in costly repairs and downtime.

Furthermore, investing in training for your team allows them to work more efficiently and effectively, ultimately increasing productivity and profits. With specialized training and knowledge, the operator can create more accurate and intricate parts, reducing the risks of waste material and errors. Proper training can also help your team identify mechanical problems early, avoiding lengthy and expensive downtime.

Therefore, when considering purchasing a CNC machine for your business, be sure to include the cost of hiring skilled operators trained to use the machine. Additionally, provide regular training to your operators, so that they can be up to date with the latest developments in CNC technology, and increase efficiency for your business. If you’re interested in learning more about how CAD can enhance your business’s design accuracy and efficiency, take a look at this article on How Industries Use CAD: Engineering.

Research the Different Types of CNC Machines Available and Their Associated Costs

Before investing in a CNC machine, it’s critical to research the different types available and their associated costs. Not all CNC machines are created equal, with different types of machines offering various functions and benefits. Some machines may be better suited for mass production and high-speed mechanization, while others may be ideal for prototyping and small-batch production. Determining what type of CNC machine best fits your business needs is an essential first step.

Once you’ve determined the type of CNC machine that is best suited for your business, it’s essential to research the associated costs. Understanding the costs can help ensure that you’re not overspending on a feature you don’t need or missing out on a valuable feature that could improve your business. Some costs to consider are the purchase price, installation and delivery costs if needed, maintenance costs, and the cost of tools and accessories to operate the machine.

In addition to basic costs, you should also look at the potential for increased productivity and efficiency once the CNC machine is operational. Investing in a high-quality CNC machine with desirable features could save your business time and money in the long run, helping to justify its upfront cost.

When researching the different types of CNC machines, it’s advisable to work closely with an experienced and reputable supplier. They can guide you through the various types of machines available, help you choose the right one for your business, and provide the information you need to make an informed purchase decision.

Think about the Long-term Benefits of Investing in a CNC Machine for Your Business

When considering investing in a CNC machine, it’s important to think beyond the initial cost and evaluate the potential long-term benefits. While purchasing a new CNC machine may seem like a large investment, it can lead to significant financial gains over time. A CNC machine can increase production efficiency, eliminate the need for skilled labor, and improve product quality. Additionally, it can help to reduce waste, lower labor costs, and improve your overall production capabilities.

To get the maximum benefit from your CNC machine investment, you should ensure that you have the necessary resources to facilitate its use. This includes trained operators, an efficient maintenance schedule, and access to high-quality software. By spending time and resources on these components, your business can maximize the value of your CNC investment, improving your bottom line and your customer satisfaction.

If you want to learn more about the impact of CAD on industries other than those in the manufacturing sector, check out this article on How Is CAD Impacting on the Fashion Industry?

Evaluate the Potential Return on Investment before Making a Final Decision

Before investing in a CNC machine, it’s important to evaluate the potential return on investment (ROI). This means looking beyond the upfront costs and considering the long-term financial benefits that the machine can bring to your business.

One way to evaluate the ROI of a CNC machine is to calculate its payback period. This is the amount of time it takes for the cost of the machine to be recouped through the savings or additional revenue that it generates. The payback period will depend on factors such as the initial cost of the machine, the cost savings that you generate, and the machine’s expected lifespan.

Another way to evaluate the ROI of a CNC machine is to estimate the increase in production efficiency that it will bring. A CNC machine can produce accurate and complex parts faster and more consistently than traditional methods. By improving production times and reducing waste, you may be able to increase your output and generate more revenue. Similarly, you may be able to shift labor costs to tasks requiring less skill or labor, freeing up resources to strengthen other parts of your business.

Ultimately, the decision to invest in a CNC machine should be based on more than just upfront costs. By evaluating the potential ROI and associated costs, you can make a more informed decision that is better suited to your business’s long-term goals.